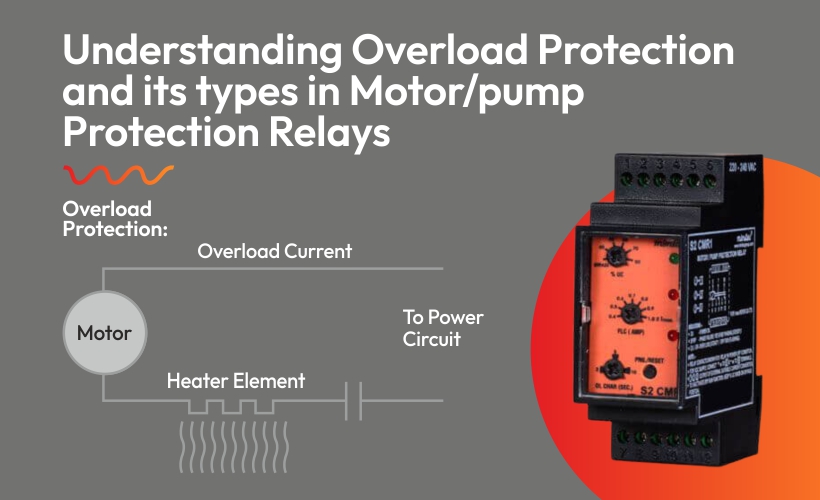

Overload protection is an essential feature of motor and pump protection relays, as it helps to protect the motor or pump from damage due to excessive current draw. When a motor or pump draws more current than its rated capacity, it can cause overheating and damage to the motor windings. Overload protection detects and responds to this condition by interrupting the power supply to the motor or pump.

Types in Motor/pump Protection Relays

There are two main types of overload protection in motor/pump protection relays: thermal overload protection and electronic overload protection.

Thermal overload protection:

This type of protection relies on a bimetallic strip or thermal element that is in contact with the motor or pump windings. As the current flows through the windings, the temperature of the bimetallic strip or thermal element increases. Once the temperature reaches a set point, the strip or element will bend or move, triggering a switch to open the circuit and interrupt the power supply to the motor or pump. The thermal overload protection is simple and cost-effective but not as precise as electronic overload protection.Electronic overload protection:

This type of protection uses an electronic device such as a current sensor or current transformer to measure the current drawn by the motor or pump. If the current exceeds a set limit, the device will send a signal to a control module that will interrupt the power supply to the motor or pump. Electronic overload protection is more precise and reliable than thermal overload protection but can be more expensive.

Some motor and pump protection relays use a combination of comprehensive protection including IDMTL characteristics and fast operations to provide optional protection for the equipment have other protective features, such as voltage protection, single phasing, reverse phasing, over current, under (dryrun) current, lock rotor, phase imbalance protection, and earth fault protection, among others, to ensure safe and efficient operation of the motor or pump.

Overall, overload protection is a critical feature of motor and pump protection relays, as it helps to prevent costly equipment damage and downtime. The type of overload protection used will depend on the specific application requirements, including the type and size of the motor or pump, as well as the operating environment.

Minilec’s motor protection relays are designed to provide reliable and accurate overload protection to prevent damage to motors and pumps due to excessive current draw. Minilec offers various types of motor protection relays, to cater to a wide range of application requirements.

Newsletter from minilec