Model

Potential Free Inputs

Potential Inputs

Alarm Annunciator

Model

Alarm Annunciators

Alarm Annunciators

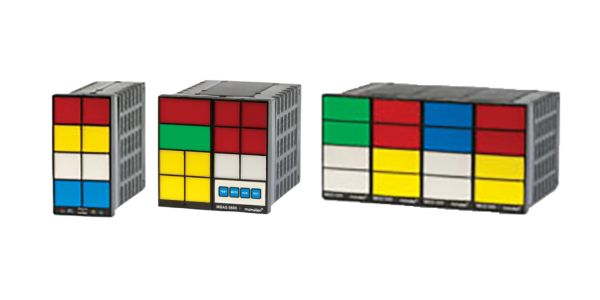

Minilec Microprocessor Based Alarm Annunciators are designed to keep an alert and watchful eye on your plant and processes. The entire range has been designed with an insight into the modern day manufacturing plant and its future requirements. Minilec Alarm Annunciators are equipped with microprocessor-based design, super bright LED facia windows, site selectable, programmed sequences as per ISA standard and thoughtful provisions for troubleshooting and maintenance. Dynamic, Alert and Responsive… These unique advantages have helped the Minilec Annunciators to be an icon in the power T and D industry and engineering establishments in India. The world class Minilec Annunciator has made its presence felt in Overseas markets.

FEATURES

- 4 windows to 128 windows

- Integral & Split models

- Microprocessor based

- Super bright LEDs for facia

- Standard operating sequences

- Any other custom- made sequences

- NO-NC & Trip Non-Trip site selectable

- Repeat relays

- Supply fail annunciation / Indication

- Choice of 3 window sizes

- Choice of five colours

- RS 232 / RS 485 Output Port having MODBUS RTU protocol or fault Input through RS 485 port MODBUS RTU protocol.

FUNCTIONS

- Continuous monitoring of input parameters

- Control of process through outputs and software

- Data acquisition & communication

- Data Storage & records through PC

ORDERING INSTRUCTIONS

- Product Family Name

- Model Name

- Aux. Supply / Control supply voltage

- No. of Inputs (Windows)

- Operating sequence

Download

FAQs

This refers to the flashing and acknowledgement sequence of the alarms, standardized by ISA (International Society of Automation). A common sequence is:

Normal: LED is off.

Alarm: LED flashes and horn sounds.

Acknowledge: Operator presses a button; horn silences, LED changes to solid.

Normal Return: The condition clears; LED turns off.

This is a crucial feature for flexibility.

Input Type: Each point can be configured on-site to accept either a Normally Open (NO) or a Normally Closed (NC) contact signal from the field device.

Alarm Logic: It can also be set to trigger an alarm on either a “trip” (contact change) or a “non-trip” (loss of power/signal) condition. This ensures compatibility with various safety philosophies.

The RS485 port with MODBUS RTU protocol allows the annunciator to communicate directly with a central computer or SCADA system. This enables:

Data Acquisition: Logging and time-stamping of all alarm events.

Remote Monitoring: Viewing the status of all alarms from a control room.

Integration: Seamlessly connecting the annunciation system into a larger plant-wide network.

Integral Model: The entire annunciator system (display, logic, power supply) is housed in a single enclosure.

Split Model: The display panel (with the LED windows) is separate from the main processing unit. This allows for a sleek display on the control panel door while mounting the electronics inside the panel, saving depth.

To configure the correct unit, you will need to specify:

- Product Family and Model Name.

- Control Supply Voltage (e.g., 24V DC, 110V AC, 230V AC).

- Number of Inputs/Windows required (e.g., 12 windows).

- Desired Operating Sequence (e.g., ISA Sequence).